Building Information Modeling's (BIM)

Sixth Dimension: Maintenance

- By Michael Fickes

- 08/01/13

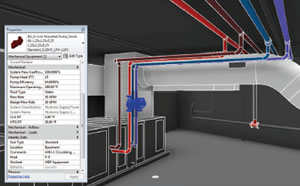

PHOTO COURTESY OF ARAMARK

Have you heard of building information modeling or BIM? If you have, chances are you know about its value as a three-dimensional design tool. Thinking of BIM as a tool, however, limits the meaning of this powerful idea.

“BIM is a process not a product. It is an intelligent three-dimensional, model-based process that supports coordinated and consistent project data throughout the lifecycle of a building,” says Brook Potter, senior business line manager in the architecture, engineering and construction group of San Rafael, Calif.- based Autodesk, maker of a BIM system called Revit.

Potter’s notion of an intelligent process is important to understanding the broad usefulness of BIM in building design and construction as well as in a building’s operational phase, which includes facility management and maintenance. In short, lifecycle from creation to demolition.

Think of it this way, during the design phase, the architect, often in consultation with the construction manager, literally constructs a digital model of the finished building.

Traditional two-dimensional blueprint drawings are virtually incomprehensible to anyone out side of the architectural and construction fields. But an owner or facilities director can understand and comment on a three-dimensional BIM building image and even fly through the interior spaces using a virtual camera.

“That’s useful,” says Michael Gonzales, a BIM user and principal with G: Architecture in the Dallas suburb of Coppell. “For instance, when we expanded a technology school campus in the K-12 space, we developed three options showing different layouts of the pods for each technology field taught by the school.

“The owner was able to thumb through the options by connecting a laptop with the BIM layouts to a projector.”

Not only that, the architect can answer questions by drilling into the three-dimensional structure, which sits on top of a vast database that includes all of the building’s systems and components from the roof to the foundation.

“If you want to check on a particular door in the database, for instance, you would see the geometry of the door and find information about the door’s properties and cost,” says Potter. “You can also add information.”

The construction of a building in virtual space has helped, and will continue to help, a construction manager perform the actual work.

The database of components can be catalogued to produce accurate estimates. The system can identify and eliminate conflicts and clashes that would ordinarily require change orders. The construction manager can also deconstruct and reconstruct the building to improve the sequencing and staging of construction.

Once the building has been constructed and commissioned, the as-built BIM plans and associated database continue the intelligent process by serving as a foundation for facility management and maintenance over the entire operational life of the building.

THE SIXTH DIMENSION

To date, BIM has proven itself in five key processes that users have taken to referring to as dimensions. “There are the design dimensions of height, breath and depth,” says Gonzales. “The fourth dimension is estimating the cost of the elements in the model. Next is construction planning, phasing and staging — the fifth dimension.”

Today, the sixth and largest dimension — facility maintenance — is emerging, continues Gonzales. The design and construction of a project cost relatively little compared to a building’s cost of operations for 20 to 50 years. BIM can help to hold down those costs while ensuring quality maintenance capable of extending the life of the building.

Some third-party maintenance providers have already adopted BIM.

ARAMARK’s Philadelphia-based education group adopted BIM after converting to a web-based Computerized Maintenance Management System (CMMS) two years ago.

“The ‘I’ in BIM is the most important piece for improving maintenance programs,” says Matt Judge, senior director of innovation with ARRAMARK. “Importing the ‘data information’ from the new construction design BIM files and the existing building BIM files into the CMMS gives us better and more accurate data and enables us to work more efficiently.”

In addition, ARAMARK maintenance teams push changes made during maintenance back into the CMMS and BIM files.

“The BIM model provides end users with a computable representation of the physical and functional characteristics of the facility and related life cycle information,” continues Judge. “For instance, the square footage data and floor type information enables us to build more accurate schedules for custodians.”

ARAMARK is currently testing BIM in a web-based dashboard system that integrates BIM files, building automation systems and the CMMS. “This will provide our managers and supervisors with all relevant information on a tablet,” Judge says. “That enables maintenance supervisors to review existing conditions and identify or even solve problems prior to sending a service technician.

“Time studies show that we can reduce the time it takes to make a repair by as much as 30 percent by issuing correct work orders.”

DO-IT-YOURSELF BIM MAINTENANCE

If your district handles maintenance in-house, you could buy and learn BIM, which would be time consuming. You could follow the example of ARAMARK and link BIM data to a CMMS system.

You can also check to see if the company that makes your maintenance management software is making any connections to BIM.

Currently, for instance, Autodesk is developing a way to export BIM data from Revit into IBM’s Maximo Asset Management application.

“An owner must perform maintenance on day one,” says Potter. “While there are excellent tools like Maximo, it can take a while to populate it with data. Our project is connecting Maximo with BIM data and with the visualization capability of the model.

“The visualization will enable a maintenance tech to see the component or system and select the right tools.”

Once your facilities department or your third party provider has access to BIM data, you will be able to replace reactive maintenance with true preventive maintenance, meaning that you will be able to track equipment performance, note subtle changes in performance that typically precede a breakdown and make repairs before the breakdown occurs.

You will have entered the sixth dimension, the maintenance dimension of BIM.