Managing Moisture

PHOTOS COURTESY OF STANTEC

Schools in rural Alaska face some of the harshest conditions on earth — below-zero temperatures,

wind, snow and driving rain.

And these villages, home for many Alaska natives, are so

remote that there are no roads to the communities. Getting

construction materials to these far-removed villages is a huge undertaking.

The communities generally have between 200 and 900

residents and schools serve the entire K-12 population.

Designing these facilities takes a unique approach suited for their

unique settings. Construction of a K-12 school is traditionally the largest,

most expensive and most important building in the village. The

schools must last 30 to 50 years in a hostile weather environment.

A strong building envelope is essential to long-term performance

of the school building. Key considerations in the design

process include understanding thermal and moisture management;

accommodating a challenging construction environment;

air tightness; continuity in vapor retarders, insulation materials

and moisture barriers; and the durability of the exterior.

Thermal and moisture management

Just recently, my freezer demonstrated the challenges that cold-weather

envelopes face. Like many Alaskans, I spend some portion

of the summer catching, cleaning, processing and storing fish. My

preferred method is to vacuum seal and freeze my fillets. After a

seemingly wetter than average summer in southcentral Alaska, I was

disappointed to find my outdoor freezer lid frozen shut and ice cascading

from the lid to the bottom of my freezer encasing my bounty.

An afternoon with the freezer off, coolers handy, fans turning

and gloves soaked, I was able to remedy the issue. But my freezer

incident highlighted two of the basic issues that building envelopes

must recognize in the Alaska heating climate: 1) air transport of

vapor, and 2) moisture management.

Air transport of vapor: In general, water

vapor moves from warm to cold. In the

case of my freezer, the water moved from

the outdoor summer air into where my fish

packs are located by sneaking through in

gaps in the seals. In the case of a school, it

goes in reverse, from the warm interior to

the below-freezing exterior or into the wall

assembly all winter long.

Moisture management of rain and condensation:

The discussion is also relevant

to seasonal changes in rainfall and humidity.

In Alaska, this summer’s higher than

average humidly caused issues with my

freezer that I have not experienced in years

with vapor and moisture seeping inside.

For schools, we must design the building

envelope to anticipate seasonal variations

in rainfall and humidity.

Stay Warm (and Dry). Schools in rural Alaska

face some of the harshest conditions on earth.

Designing these facilities takes a unique approach

suited for their unique settings. Key to success

for a strong building envelope is the selection of

materials that will endure in rural Alaska’s harsh

environment. The structural frames in the schools

we design are either a mix of glulam wood beams

and steel or all steel. The key design goal is to

limit any penetrations of structure from cold to

warm space. The best way to ensure that you will

have long-lasting schools is effectively control the

vapor and moisture in the thermal envelope.

Key to success for a strong building

envelope is the selection of materials that

will endure in rural Alaska’s harsh environment.

Structural Insulated Panels (SIPs) have

proven invaluable on multiple rural school

projects because they allow a tight envelope

to be constructed quickly and easily. The SIPs

consist of wood sheathing (OSB or plywood)

sandwiched onto a core layer of Expanded

Polystyrene Insulation (EPS). The thickness

of the roof and wall panels are constructed

with and based on dimensional lumber sizes

and provide options for R-value or thermal

resistance based on 2x4, 2x6, 2x8 and 2x12

standard thickness. Typically, the SIPs are

used on the walls, roof and building soffits.

Accommodating realities in

construction

Seasonal barge schedules set the

timetable for rural Alaska construction.

The villages are not connected the state’s

road system. Everything is delivered by

boat or airplane. The high cost and space

limitations of air freight mean that a vast

majority of materials and equipment arrive

via barge — and those barges only travel

about half the year. It is simply the reality

of construction in remote Alaska.

If the design and bidding of a project is

on schedule and the project site is ready,

construction materials can arrive on the

first barge of the season, generally in May.

This allows for four or five months of site,

foundation and framing construction to

begin to accept the SIPs. The roof generally

goes on in August/September, which

is traditionally one of the wettest times of

the year. In recent years, Western Alaska

averages about 3¼ inches of rain in August

and 2¾ inches in September.

Knowing that the roof will likely see

heavy rains during construction, the school

roof assembly is built with a vapor permeable

self-adhered membrane and a 3½-inch

ventilation space above that sits atop the

SIPs. Above this is another layer of plywood,

fully adhered non-permeable waterproof

membrane and metal roofing. The vent

space offers two key functions: 1) it allows

the roof panels to dry from anticipated wetting

that occurs during construction, and 2)

it allows for future moisture to vent and dry

out, ensuring a long functional roof life.

Air tightness

My freezer experience proves that vapor

transport via thermally driven diffusion and

air transport doesn’t take a day off. Just a small

leak in the freezer door seal allowed nearly a

gallon of water to slowly enter, condense and

freeze over the course of two months.

It is the same principle with a school.

The exterior envelope must be tight. Every

wall penetration is an opportunity for air

leakage and moisture damage. Limiting

the penetrations from interior to exterior

within the thermal and vapor barriers improves the tightness of the envelope.

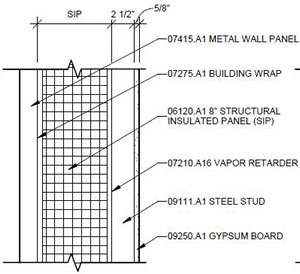

Heating climates require the vapor

retarder (polyethylene plastic sheet) to be on

the warm side of the wall assembly. In typical

construction, every outlet or light switch

on an exterior wall is a potential leak. To

limit this potential, the wall system assembly

has the vapor retarder installed over the interior

face of the SIPs without penetrations.

Of course, a school needs lots of outlets,

data wires and plumbing supply lines. Our

designs place 2½-inch metal furring inside

the SIPs to house all those elements within

the warm space of the building. Gypsum wall

board is the interior finish.

Because of the separation, all outlets,

pipes and penetrations are no longer potential

liabilities. It also is easier to update the

school for future use without damaging the

vapor retarder or requiring an expensive

modification to the envelope.

Thermal envelope continuity

The structural frames in the schools

we design are either a mix of glulam wood

beams and steel or all steel. The key design

goal is to limit any penetrations of structure

from cold to warm space.

In the subarctic region where most of

these schools are going up, moisture in

the air will condense on building elements

(like moisture on a cold glass) and steel,

especially with its conductive factors, will

transfer that cold all the way into the building.

As the cold moves into the school, it

collects moisture from the heated air and

releases it as condensation on other interior

building finishes resulting in mold, mildew

and possible decay. To reduce this, the best

practice is to completely wrap or contain

all structures within the thermal envelope.

In some instances, such as support cantilevers,

it is impossible to have them within

the envelope. To limit condensation issues,

cantilevers and other similar elements are

built with wood or other material with a

limited ability to conduct temperature.

Exterior durability

When the school is complete, the majority

of the important building envelope

elements are hidden behind the exterior

finish. Especially in remote Alaska, the

finish isn’t simply icing on a cake, it plays

a crucial role in the overall functionality of

the building and the envelope.

All of these remote Alaska schools are

the center of the community and most are

in use 12 to 15 hours a day. Even after the

doors are locked, children are still playing

at and around the school. The constant

activity means that the wall, window and

door surfaces are within arm’s reach or

stone’s throw and need protection. Finishes

need to be affordable, easy to install, easy

to maintain and tough.

For the exterior walls, a heavier gauge

(generally 22 gauge) large rib metal siding

installed with flutes vertically aligned

works well. It is more difficult to dent,

allows the exterior to dry and is reasonably

priced. The gauge can be lessened and the

same profile metal used at adjacent less accessible

areas, resulting in a consistent look

but with some cost savings. High quality

vinyl windows with double or triple panes

are the standard choice for these schools.

Protecting the windows is essential. The

best practice is covering the exterior windows

with a high-quality polycarbonate

sheet. The polycarbonate is nearly as clear

as glass and with proper detailing is easily

replaceable without removing the windows.

Moisture outside, comfort inside

Controlling vapor and moisture in the

thermal envelope means efficient, long-lasting

schools. Keeping it out of my freezer

means I get to enjoy salmon all winter and

have a place to keep next season’s catch.

About the Author

Dale Smythe is a lifelong Alaskan and a senior architect at Stantec. He is the project manager on five current and recent school projects in the rural Alaska villages of Quinhagak, Kwigillingok, Koliganek, Nightmute and Kwethluk.