Energy Infrastructure Upgrade to Save Georgia Tech $11.7M

Georgia Institute of Technology in Atlanta, Ga., recently partnered with facility energy solutions provider ABM Industries to upgrade campus STEM labs—and save about $11.7 million across ten years in the process.

The university discovered that about 30 percent of campus energy use came from 5 percent of its square footage. After identifying that campus lab spaces were consuming such a high proportion of energy, it set about looking for ways to cut lab space energy cost, reduce its carbon footprint and provide safe and reliable working environments.

According to a news release, an energy savings performance contract with ABM led to the decision to upgrade fume hood controls for about 140 lab spaces around campus with no upfront cost. During the 2020 fiscal year, the project reduced energy consumption in two campus buildings—the ES&T and UA Whitaker science buildings—by 73.7 percent and 52.7 percent, respectively. It also surpassed the guaranteed utility cost savings with an additional reduction of $173,167.

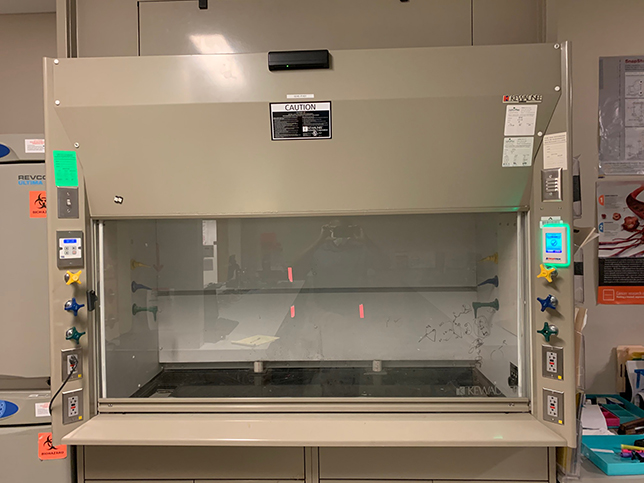

The fume hoods and snorkels have new safety controls that help improve the cost-effectiveness of proper ventilation and increase reliability. On-site technicians also now receive real-time data that allows them to respond to performance issues that could decrease airflow or result in potentially expensive downtime. The collective set of data also allows for ease of preventative maintenance to optimize performance.

The installation also meant coordinating with research teams around campus to minimize disruption to millions of dollars’ worth of ongoing research project. ABM coordinated with Georgia Tech leadership, Environmental Health and Safety, lab safety officers and research teams to complete the necessary work in each given lab space in less than a week.

“This project required a high level of coordination among a wide range of stakeholders to balance safety, functionality and efficiency while conforming to a very tight design and construction schedule,” said Greg Spiro, Senior Mechanical Engineer, Design and Construction at the Georgia Institute of Technology. “The ABM team completed construction ahead of schedule and the project has helped reduce energy usage.”

About the Author

Matt Jones is senior editor of Spaces4Learning. He can be reached at [email protected].