Zero Tolerance

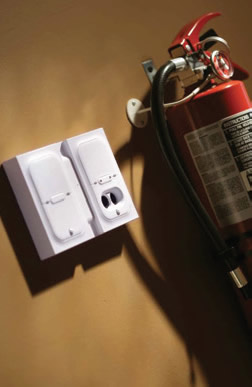

A few articles ago, I discussed implementing technology to reduce inspection times and increase staff time to tackle other life safety issues in your schools. I don’t often dedicate another article so soon to a subject recently covered, I am breaking this rule and want to revisit monitoring technologies available for fire extinguishers, electrical panels, coolers and egress systems and their ability to reduce inspection citations from fire or OSHA regulators.

A few articles ago, I discussed implementing technology to reduce inspection times and increase staff time to tackle other life safety issues in your schools. I don’t often dedicate another article so soon to a subject recently covered, I am breaking this rule and want to revisit monitoring technologies available for fire extinguishers, electrical panels, coolers and egress systems and their ability to reduce inspection citations from fire or OSHA regulators.

I just returned from a conference where fire prevention and OSHA regulators were in attendance. During a break, the topic of common violations between fire inspections and OSHA inspections came up. The discussion determined that obstructed extinguishers, electrical panels and exit routes, as well as fire extinguishers not being inspected on a monthly basis, were in the top 10 most frequently cited violations. Both fire and OSHA staff agreed that it is possible to always find an obstructed extinguisher or one that has not received its monthly or yearly inspection.

The OSHA inspector indicated that first-time offenses for violating an OSHA regulation are capped at $7,000, unless it is found to be a willful violation. A repeat violation increases the penalty to $70,000. The inspector was quick to rattle off locations where fines exceeded $233,000 and $144,000 for repeat violations for buildings.

I shared with both inspectors that there is technology that can eliminate first-time violations for extinguisher, exit system and electrical panel obstructions, as well as missed monthly inspections. I told them about a location that installed 14 monitored points covering extinguishers, electrical panels and a temperature sensor alarm in a pharmacy refrigerator (while not typically found in K-12 facilities, there are other temperature sensitive locations that the technology would be applicable too). The devices were part of a seven-month facility test to demonstrate that active monitoring of these locations would reduce or eliminate obstructed devices, and in the case of the temperature sensor, protect extremely costly medicine.

The fire extinguisher monitoring devices can produce an alert and a trouble signal. The alert signal is produced when the extinguisher is removed from is designated location (this also cuts down on tampering). The trouble signal is activated when the extinguisher, exit or electrical panel is obstructed.

The trouble signal is also activated when there is abnormal pressure in the extinguisher.

Data gathered from the seven months clearly showed the benefits of the monitoring technology. During the first four months all the fire extinguisher monitoring devices had at least one obstruction trouble alarm and several had multiple troubles. At first, the obstruction troubles were concerning, but after the first few months the obstruction troubles became less frequent. Employees went through a learning curve and then realized obstructions were not going to be overlooked.

The inspectors both agreed that these violations are low hanging fruit and with monitoring technology any school can eliminate the need for inspectors to cite for obstructions and improper inspections. One of the inspectors said a Joint Commission Inspector had told him that extinguishers are expected to be written up, regardless of if only one extinguisher of 1,000 is unchecked. It’s a 100-percent compliance item — 99.9 percent could be in compliance — but you will still be cited.

Installing monitoring technology takes hundreds or thousands of points of regulatory risk down to no points of risk for monitored locations. You will eliminate one of the simplest items for an inspector to question or find a deficiency. In addition your egress routes, electrical panels and extinguishers must all accessible for use in an emergency.

One inspector asked if the technology to monitor these items is available from multiple companies. The answer is yes, all major fire alarm companies have the ability to install this equipment.

This article originally appeared in the issue of .

About the Author

Mike Halligan is the President of Higher Education Safety, a consulting group specializing in fire prevention program audits, strategic planning, training and education programs and third party plan review and occupancy inspections. He retired after twenty six years as the Associate Director of Environmental Health and Safety and Emergency Management at the University of Utah. He frequently speaks and is a recognized expert on residence hall/student housing fire safety and large scale special event planning. He also works with corporate clients to integrate products into the campus environment that promote safety and security.