Lean Cleaning as a Path to Quality

Cost control and healthy cleaning in K-12 environments.

- By Allen P. Rathey, David Mudarri

- 09/01/16

Lean is about finding the shortest path to quality. Companies

like Toyota helped define what it means when producing

cars. Lean process can help you define and ensure quality cleaning

in your school or district with healthier outcomes at lower cost.

Lean is about finding the shortest path to quality. Companies

like Toyota helped define what it means when producing

cars. Lean process can help you define and ensure quality cleaning

in your school or district with healthier outcomes at lower cost.

Whether Building Cars or Cleaning –

Take the Five Steps

Whether building cars or cleaning programs, the steps to quality

are the same:

1. Know the Goal – Define Value

2. Break the Job Into Baby Steps

3. Eliminate Steps, Improve Outcomes, Achieve Flow

4. Standardize and Improve

5. Tap Tacit Knowledge or Experience and Share with the Team

Know the Goal – Define Value

Discuss this with your staff and customers, build consensus

and draft a mission statement, such as: “We will produce clean,

healthy, attractive and cost-effective school facilities by first

understanding then addressing school admin, faculty and student

needs, then delivering consistent, high quality cleaning by eliminating

defects and variability in the cleaning process.”

Break the Job Into Baby Steps

This is the key to achieving the goal in step one. You must know

exactly which tools and processes enable reaching the goal. For

example, the steps in a classic floor cleaning process are as follows:

Mop and Bucket Cleaning

1. Sweep floor with dust mop and dispose of soil.

2. Fill a standard mop bucket with water, add chemical.

3. Dip mop in bucket and wring.

4. Mop floor.

5. Rinse and wring mop.

6. Apply mop to floor, continue “cleaning” and redepositing some soil.

7. Rinse and repeat.

8. Rinse out dirty bucket and plan additional cleaning to restore floors.

Eliminate Steps, Improve Outcomes, Achieve Flow

To eliminate steps and while improving outcomes, a classic

lean application being used by forward-thinking schools

is to abandon traditional mops and mop buckets in favor of

battery-powered systems that utilize a mop-bucket-sized rolling

platform to dispense cleaning solution onto floors, agitate it then

vacuum it off in one step, insuring consistent concentration of

cleaning solution while eliminating the spreading of dirty water,

some pre-cleaning, and follow-on floor care. Here are the steps in

this new method:

New Lean Method (with battery-powered cleaning platform)

1. Sweep floor with dust mop and dispose of soil (this can be

reduced or eliminated in some cases as the vacuum of the

battery-powered cleaning platform can pick up light soil without

a separate step).

2. Fill cleaning bucket of battery-powered unit, add chemical.

3. Open dispensing spigot to release clean solution onto floor as

you walk, simultaneously agitate by walking across floor with

onboard microfiber scrub pad in “down position”, pick up

soiled solution as you walk with squeegee/vacuum tool engaged

on floor behind cleaning pad.

4. Empty and rinse soiled solution tank.

Since the choice of tool determines the steps involved, select

tools that enable job completion with the fewest steps, then identify

and diagram the value stream to eliminate waste. Simplify

jobs by identifying each and every crucial step and eliminate waste

or backtracking.

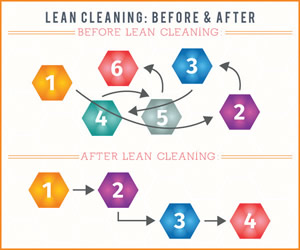

The accompanying Lean Cleaning chart illustrates how reducing

steps cuts waste and improves workflow. Apply the principles

to develop cleaning flow charts (examples include dusting, restroom,

floor care and other lean process flowcharts).

Reduce or eliminate stop-start or task-switching interruptions

and apply the new lean processes throughout your operation,

resulting in a significant step and labor reduction.

Standardize and Improve

Standardize best current cleaning practice. The goal of standardizing

is to help ensure cleaning is done the same way every

time for consistency.

It evens-out the workload so each team member works steadily

but not hard (think tortoise not the hare). Standardizing provides

a baseline for improvement.

Continuous improvement is only possible when there is clarity.

Create video (with permission) of field cleaning activities, view the

video as a team, then adopt group improvement suggestions and

build them into the new, better lean cleaning standard.

Tap Tacit Knowledge or Experience

and Share with the Team

Tacit knowledge is gained through experience. Use a buddy

system of training to pair new hires and workers needing coaching

with accomplished team members. Help team associates grow and

realize higher potential.

Remember Your Workers

Lean is about reducing waste, not the workforce. It is a tool for

improving the work through the workers. A Toyota executive said:

“…We had a saying, ‘mono zukuri wa hito zukuri’ which

means ‘making things is about making people.’ If people want to

succeed with lean… they have to emphasize people development

and making leaders capable of delivering improvements.” (from

the book, The Toyota Way, by Liker and Meier)

Lean is about streamlining processes. Workers in lean cleaning

work smarter not harder, and adopt a set of tools, behaviors and

practices to reach higher levels of greenness, healthfulness, quality,

cost-effectiveness, and overall improvement.

This article originally appeared in the issue of .

About the Authors

Allen P. Rathey is an educator specializing in Healthy Facilities. He has assembled an advisory group of dozens of scientists, PhDs, facility and public health experts, who share his passion for helping people everywhere create and maintain safe, healthy, indoor environments. He is past-president of The Housekeeping Channel (HC), The Healthy House Institute (HHI), and The Healthy Facilities Institute (HFI). He is the principal of Winning Environments, LLC, promoting best practices that enhance the living environment. Call him @ 208-724-1508 or email [email protected]. Allen provides advisory and consulting support, in person, by phone, via published articles, social networks, and through seminars and webinars.

David Mudarri, Ph. D., is a retired senior EPA advisor, devoted to advancing public health through indoor air quality education and the development and promulgation of state-of-the-art process and tools. After retiring from EPA, Dr. Mudarri served as the technical editor of ASHRAE's Indoor Air Quality Guide, authored IEHA’s Clean and Healthy Schools For Dummies, and produced papers on the impact of climate change on indoor air quality, building codes and indoor air quality.