Enabling the Future of the Campus Experience

Infrastructure Renewal and Modernization at The University of New Hampshire

By Elizabeth Nolder, Brad Charters, and Michael Bean

Universities across the United States are making bold moves to energize enrollments––from grade-based admissions guarantees and standardized testing alternatives to on-campus housing assurances and impressive amenities. For many institutions, these incentives are often matched by new, state-of-the-art academic buildings and research facilities. However, a majority of those same universities are sitting on decades-old infrastructure networks buried beneath their sprawling grassy quads and cobblestone pathways. A university can't rank for research without reliable, stable power, and prospective students. Potential new students can’t take a tour of a green that’s fenced off because of an underground steam failure.

As administrators look to the future of the campus experience, they must first understand and account for the importance of campus utility renewal projects––engaging with skilled engineers to assess the conditions and capacities of the current infrastructure and roadmap investments to fortify the campus for centuries to come. If planned and phased properly, modernization can occur with minimal student life disruption and potentially even alongside above-ground additions if designed intentionally. Most importantly, a reliable, safe, and efficient infrastructure network ensures that the academic mission and vision are not sacrificed––which, after all, is what students are enrolling for at the end of the day.

This strategy for campus renewal and modernization was top of mind for the University of New Hampshire (UNH) as it embarked on one of its most significant infrastructure improvements in recent history––relocating a substantial portion of its utility distribution network connected to the Combined Heat & Power Plant (CHP).

Image courtesy of Charters Brothers

Modernization: Laying the Groundwork

UNH established its Durham campus in 1893 and has grown from an enrollment of less than 100 to over 15,000 in the years since. Its utility network has evolved alongside it, distributed through a series of underground tunnels and direct buried piping that feeds campus buildings. Over time, the structural integrity of these tunnels can deteriorate, creating risks for the utility services within them, as well as the roads and walkways above them. Knowing this, in 2020, UNH engaged RMF Engineering to complete a condition assessment of a portion of the campus' tunnels, which revealed sections of deterioration that could impact the reliability of the active utilities if left unaddressed.

Leveraging its experience in unique underground utility distribution systems and in-depth knowledge of the challenges and considerations associated with working on a college campus, RMF derived from its assessment the full spectrum of repairs required and the associated costs, presenting UNH with a complex mix of findings and options for upgrading the existing infrastructure. Ultimately, the university opted to abandon a portion of the tunnel beneath an older structure already slated for demolition and relocated the active utilities in direct buried piping in a new parallel location. This approach introduced complexities at every stage, requiring a highly coordinated, phased plan executed by an expert team.

Providing civil, structural, mechanical, and electrical design and construction administration services for the relocation, RMF worked closely with Charters Brothers Construction (CBC)––which has managed and completed numerous utility projects for UNH over the years––to navigate each challenge while minimizing the impact on campus. RMF and CBC's careful phasing of the project remained agile throughout the process, adapting to situations as they arose, including navigating challenging site logistics, product lead time delays, safety requirements, and student life considerations.

The Campus-Scale of Impact

The significance of this particular project for UNH was due in large part to the sheer scale of its footprint. RMF's new underground utility design was situated beneath the heart of UNH's Durham campus and included over 800 linear trench feet of steam, condensate, dual temperature water supply and return, and a concrete encased duct bank to replace a critical section of the campus loop immediately outside of the CHP. Any work to the university's active utilities network would have varying degrees of influence, but re-siting a substantial portion of the infrastructure distributed from the CHP could have implications across campus.

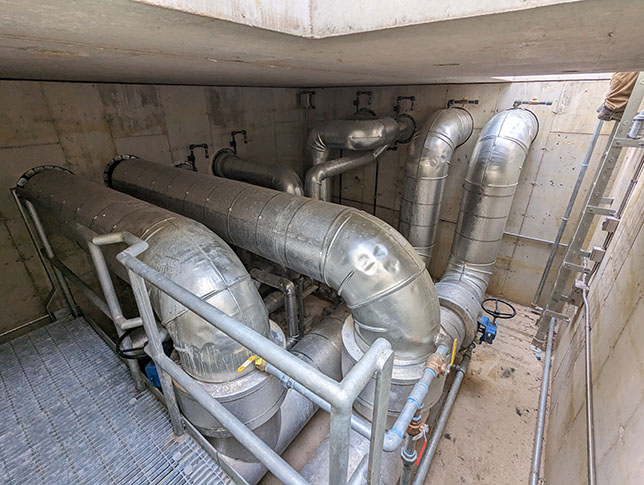

The new underground piping alignment runs parallel to the existing tunnel system, which heads south and east through central campus at the intersection of College Road and Library Way––meaning complex connections to the existing infrastructure within the Plant, Pettee Hall, Morrill Hall, College Road Tunnel, and Library Way Tunnel. This strategy was intended to minimize the impairment of the campus loop system via a short-term cutover, but would not be without its challenges. The bulk of the pipefitting work had to be completed between the critical milestones of the CHP shutdown and cut over to the cooling season following commencement, and the start of the subsequent fall of 2022 heating season. Further, coordination with the existing––and already congested––underground utilities was critical for the design and subsequent task of excavating, forming, reinforcing, and placing a 20’ x 20’ cast-in-place concrete vault to house the piping, tees, and valves that facilitate campus-wide utility distribution.

Purely due to the overall width of the trench needed to support the large diameter piping and required clearances, a significant amount of green space, hardscapes, and the roadway were disrupted and then restored after the project. Included within that footprint was a road that provided access to another ongoing construction site on campus, as well as a fire lane for several buildings adjacent to the project site that had to be maintained and approved by the State Fire Marshal for student access.

Image courtesy of RMF Engineering

The Power of Coordination

To execute RMF's highly technical underground utility design while balancing a complex construction schedule, CBC developed a coordinated procurement strategy with the piping manufacturer which broke down the more than four thousand feet of pipe, valves, and fittings into eleven separate deliveries across the summer. As challenges mounted, CBC worked with RMF to resequence its original plan on several occasions, workshopping routing solutions and evaluating stress analyses, allowing segments of the project to continue moving forward while others awaited delayed shipments.

Coordination and flexibility were critical in navigating the inevitable unforeseen obstacles that emerged as summer turned to fall. Despite UNH’s extensive and up-to-date records of the underground utility networks on campus and the pre-construction investigative efforts during RMF’s design process, existing, undocumented telecommunications and alarm wiring duct banks were discovered that interfered with the initial routing plan. The wiring fed the campus dispatch center and could not be relocated or disrupted at all, so the only option was to find an alternative routing for the new piping. RMF and CBC worked together to find a solution that would meet the design requirements while also making the best use of the fabricated pipe already on site.

Image courtesy of RMF Engineering

Solutions Today for Tomorrow

Understanding existing campus assets will enable UNH to more effectively and strategically plan future utility renewal and growth-oriented projects––allowing administrators to focus more on the "want to have" improvements than the "need to have" investments. This project provided an opportunity for UNH's Utility team to laser scan the new utility runs as they were installed, tested, and backfilled, as well as verify the existing infrastructure the campus already had in the ground––documenting the as-built locations via GIS mapping for the archives and future utility locating. RMF and CBC also worked together during the project to ensure the ease of safe operations and maintenance for many years to come with the inclusion of additional meters and valves within the plant and remote operating valves at the site structures to allow access from the surface.

These measures contribute to a more reliable, safe, and efficient utility infrastructure network that serves students, faculty, and staff equally. UNH's new system went live in late November of last year, successfully bypassing the aging tunnel and restabilizing the heart of campus for its next era––complete with all-new hardscape and landscape for the academic community. In addition to enabling the advancement of UNH's mission, the modernization project has since received an Associated Builders and Contractors (ABC) Excellence in Construction Award.

Elizabeth Nolder, PE, is a Principal with RMF Engineering. Brad Charters is a Principal and Michael Bean the Vice President of Project Management with Charters Brothers Construction.