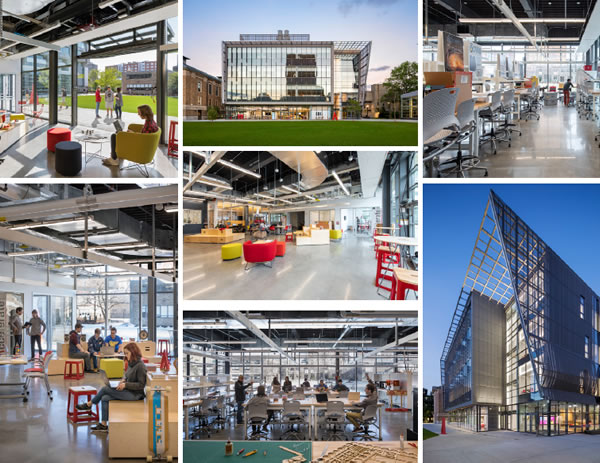

Wentworth Institute of Technology: Center for Engineering, Innovation, and Sciences

PHOTOS © ALBERT VECERKA / ESTO

The advancement of

technologies for fabrication and

the increased interest of educators

of hands-on learning environments has

prompted a proliferation of makerspaces

in college and universities nationwide. The

new 75,000-square-foot Center for Engineering,

Innovation, and Sciences at Wentworth

Institute of Technology in Boston,

designed by Leers Weinzapfel Associates,

comprises a dynamic, multidisciplinary

environment for such collaboration among

students of biology, civil engineering,

mechanical engineering, and two of the

Institute’s newest programs, biomedical

and biological engineering.

Open to the quad on one side, a city street

on another, and the campus circulation spine

on a third, the building’s fully glazed first

floor was designed to advertise the activity

inside and entice students to participate in

the creativity they see from outside. The

public lobby is a gathering venue that can be

transformed from a collection of informal

furniture to a lecture space and a building-long

display that exhibits student work. Vertical bifold glass doors on the quad allow

public visibility as well as an easy flow from

inside to outside to allow work to be moved

into and out of the building. The Center’s

academic makerspace is on the other side of

the lobby, facing the city street.

The goal for the interior of these spaces

was to be as flexible as possible in order

to adapt to student needs. Tables can be

flipped and nested, chairs can be stacked,

whiteboards can be brought in and out,

and modular, stackable wooden boxes can

become stools, benches, and sitting steps.

Proximity to tools for fabrication was also a

design priority, and they are easily accessible

in an adjacent room. Two dedicated project

rooms also line one wall, and even these

can be opened up to become a larger project

space in this new breakthrough facility.

This article originally appeared in the College Planning & Management September 2019 issue of Spaces4Learning.