Applications of Closed Loop Food Systems in Urban Design / Architecture

NZ4 Global Alliance Life Style Science Parks / Technology Cluster HUB’s

Courtesy of Bruce Haxton, The NZ4 Global Alliance©

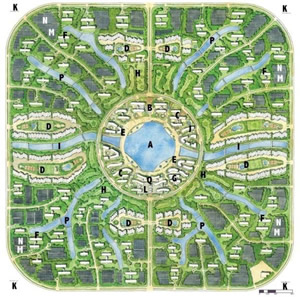

2011 Net Zero Energy / Water Science Park Prototype

Courtesy of Bruce Haxton, The NZ4 Global Alliance©

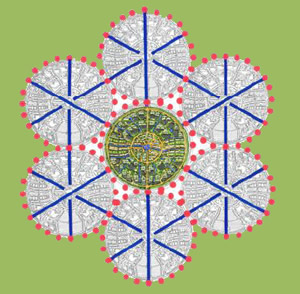

2013 Net Zero Energy / Closed Loop Science Park

Courtesy of Bruce Haxton, The NZ4 Global Alliance©

2015 EcoScience City©: Net Zero Energy / Closed Loop

In 2011 the NZ4 Global Alliance developed an 1100 acre Net Zero Energy / Net Zero Water Prototype design for a Science Park and presented that at the International Association of Science Parks (IASP) World Conference in Denmark. Two years later they designed; in 2013 they design the Net Zero Energy / Closed Loop Prototype design, which included organically grown food for the 12,000 people anticipated in the 12,000 acre Science Park. Now in 2015, they have completed a “Life Style” Urban EcoScience City Prototype design for the 2015 I2SL International Conference in San Diego. Each design is specially designed for each project location and would include both passive and active system design. The 2015 design features aquaculture, aeroponics, and hydroponic design concepts to produce organically grown food for the Eco Science City residents. The buildings are all anticipated to be Net Zero facilities and the master planning is designed to harvest water and use it as a “heat sink” to heat and cool the buildings. A vehicular free / pedestrian focused planning concept is used for the EcoScience City of the future.

Bruce Haxton, AIA, Architect, NZ4 Global Alliance Co-Team Leader:

Bruce Haxton 7.27.2015

“Our team got involved in Net Zero Closed Loop design about 5 years ago. We have been developing design prototypes for Science Parks and urban environments; finally getting to the point of designing a Net Zero Closed Loop urban environment with its own closed loop food system. This has led us to food research / studies in much greater detail; closed loop food systems for developed countries, developing countries, and potential space exploration environments. Our team felt it was very important to reach out and start developing this needed expertise in our K-12 schools.”

2011 IASP Net Zero Energy and Water Life Style Science Park / City

The 1100 acre net zero energy and water “Life Style Science Park” was developed and presented at the IASP World Conference in Copenhagen, Denmark in 2011. The water resources are saved and used for recreation and as “thermal sinks” to help heat and cool the energy efficient (Net Zero facilities). The science community has a Magnet University at its center along with typical city services including eating and entertainment facilities along the central water feature. The 18 hole golf course is designed to complement the other sports activities in the city and provide needed green space. The annual water harvesting and use has been balanced to be net zero. The amount of trees on site is coordinated to change the carbon dioxide back into oxygen to the number of residents in the science park / city. This design also features “technology incubators” to help the community become also economically sustainable by developing future employment opportunities for the residents.

2013 IASP Net Zero Energy and Water Life Style Science Park / City Closed Loop Prototype

The 12,000 acre net zero energy and water closed loop utilizes algae and duckweed to purify the water to help create this closed loop system. The NZ4 Team took the 2011 IASP scheme and developed it into an organically oriented closed loop science city that creates its own organically grown food. The total city and farming of 12,000 acres would produce enough food for the 12,000 residents. The water and energy needs of the entire facility would be met and customized for the climate of the proposed project.

2014 IASP Net Zero Energy Community Assistance Centers Closed Loop Prototype

The concept was to design a prototype Community Assistance Center® (CAC) for Developing Countries. The prototype consists of: 1) Health Care Center of 18 hospital beds with an emergency area/operating room, 2) Multi Purpose Assembly Area for the community for both religious services and 3) Educational Training Facility for various types of teaching (traditional, computer, and distance learning). The CAC would also be net zero energy and water, as well as growing its own food in a closed methodology.

2015 I2SL Conference “Futuristic Urban EcoScience City©: Life Style Science City, Net Zero Energy, and Closed Loop Design”

This design prototype is meant to be a closed loop design for a EcoScience City of the Future. The entire design is a 6,300 acre pedestrian focused “Live, Work, Play, and Educate” urban community. The difference between this prototype and the IASP 2014 Prototype is that it is urban and uses advanced “vertical aquaculture farming and aeroponic food growth systems” designed food farming methodology. Richard Stoner and NASA developed the Aeroponic system that is now being commercialized by AgriHouse. Dr. Addison Lawrence has previously developed the Shrimp Vertical Farming system that is used around the world. Tamra Fahkoorian is the Director for the International Lemna Association (ILA) and Founder of GreenSun Products, LLC.

The NZ4 Global Alliance Team

The NZ4 Global Alliance is a consortium of professionals that work as separate entities or together as a team to meet the needs of the various clients for high performance and net zero energy buildings; the following are NZ4 Global Alliance members:

Bruce Haxton, NZ4 Co-Team Leader

Rick Cantwell, NZ4 Co-Team Leader, President of Odell International

Richard Stoner, AgriHouse

Tamra Fakhoorian, Algae/Duckweed Expertise

Dr. Addison Lawrence, Vertical Shrimp Farming Expertise

John Andary, Integral Group

Tom Kubala, The Kubala Washatko Associates

Fred Meade; Science Park Consulting

Michael Perciali, Green cGMP Architect;

Bry Sarte, President of Sherwood Design Engineers

Peter Why, International Science Park Consulting

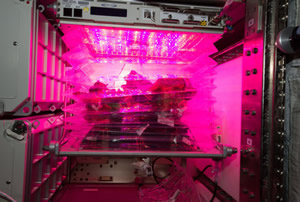

Kennedy Space Center and NASA’s Veggie System

Veggie System lettuce ready to eat

NASA KSC Food Research Narrative Quote:

June 19, 2014 Massa at NASA "Our end goal is for food production, and Veggie is our first step for NASA to be able to achieve food production systems for space," Massa said. "We're looking at developing what we call a pick-and-eat capability for space station within the next few years."

Space Applications

NASA has been studying crop support systems for more than 30 years, with a goal of designing a self-sustaining life support system for crew members. But no large-scale crop production tests have yet been conducted in space. The International Space Station provides an ideal platform for producing a larger volume of plants in a controlled environment using limited power. Growing plants in space provides crew members with fresh foods to supplement their diets, as well as a positive effect on morale and well-being.

Earth Applications

Plants cultivated on the International Space Station can be used for educational outreach activities on Earth. In addition, the station offers limited size and power capabilities, which can provide insight into plant cultivation methods for small spaces with minimal energy.” [1]

NASA or National Aeronautics and Space Administration

Veggie System with food inside

NASA Veggie System Narrative

“The overall goal of Veg-01 is to demonstrate proof-of concept for the Veggie plant growth chamber and the planting pillows. This research builds upon hardware development via an SBIR grant to ORBITEC for the initial prototype Veggie units with subsequent hardware development for next-generation units. Both ORBITEC and KSC have been involved in plant growth optimization of the Veggie hardware and testing and collaboration have resulted in the development of the pillow planting concept to interface with the Veggie hardware. Through numerous tests the VEG-01 science team has refined the pillow concept and selected growth media and fertilizers, plant species, materials, and protocols for using the pillow concept in Veggie to grow healthy plants that can provide crew with food and recreation. The pillow concept is designed to be low mass, modular, require no additional energy and be very low maintenance. Pillows of different sizes have been designed to accommodate a wide variety of plant types and different types of growing media.

NASA or National Aeronautics and Space Administration

ISS Crew Members eating Veggie System lettuce on International Space Station

The primary goal of the Veg-01 testing will be to demonstrate plant growth in the Veggie hardware using lettuce as a test species. Plants will be grown in two different sizes of arcillite, a calcined clay media. This test will help us compare root zones of the two media sizes to determine water and root distribution in the different sized-particles to provide recommendations for future Veggie investigations. Shoot samples will also provide information on any growth anomalies when compared with ground controls and will provide information on microbial growth and food safety. Photographs will be used to assess plant growth rates and plant health. A data logger will record the environment within the Veggie hardware. Crew questionnaires will provide insight into the appropriateness and thoroughness of the crew procedures for Veggie hardware and plant growth operations.

Pillows are single use and thus reduce the chances of microbial contamination of the Veggie hardware and produce. A major aspect of the proof of concept flight, Veg-01, is to collect baseline microbial data from plants and pillows grown on the International Space Station (ISS). Ground testing has demonstrated very low microbial levels on lettuce plants grown in Veggie-relevant conditions. Discussions with space microbiologists, flight surgeons, and space food technologists at JSC indicate that if microbial levels are sufficiently low the crew could consume the fresh produce without sanitizing. For crops that naturally have higher levels of microorganisms (e.g. radishes, which grow in contact with water and nutrients) a space-rated produce sanitation method must be developed and tested.

The baseline data collected from the Veg-01 flight will be a resource for future Veggie investigations. This information will provide data on necessary procedural changes, hardware upgrades, or horticultural options as Veggie becomes an integral part of ISS expeditions in the future. “[2] Source [1 & 2 ]:

NASA Kennedy Space Center

NASA background information:

Meals Ready to Eat: Expedition 44 Crew Members Sample Leafy Greens Grown on Space Station

Veggie Plant Growth System Activated on International Space Station

Researchers Mirror Space Station's Veg-01 Harvest in Kennedy Space Center Lab

Plant Growth Experiment To Get Underway on Station

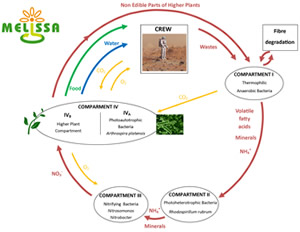

European Space Agency (ESA) MELiSSA Closed Loop Food System

European Space Agency 2015

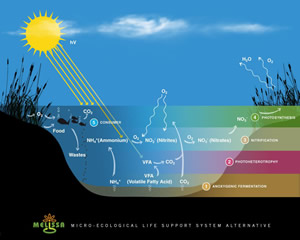

Melissa Closed Loop Food System developed for Space Exploration

MELiSSA – An Artificial Ecosystem for Deep Space Exploration

Long-term manned missions in space are heavily limited by the need of constant resupply of food, water and oxygen to the astronauts. For future manned missions, e.g. to Mars or even an extended stay on a planetary surface these limitations have to be overcome. The European Space Agency’s project to extend the capabilities of more independent human exploration in space is called MELiSSA: Micro-Ecological Life Support System Alternative. MELiSSA aims to develop technologies for a so called regenerative life-support system. The driving element of MELiSSA is the recovery of food, water and oxygen from CO2, minerals and waste.

European Space Agency 2015

MELiSSA Lake: The aquatic ecosystem the MELiSSA loop is based on with some of the used processes.

European Space Agency 2015

MPP compartment III and IVa: A view of the MELiSSA pilot plant. Compartment IVa see above, compartment III is used for nitrification.

The MELiSSA concept is inspired by an aquatic ecosystem such as a lake. To transfer the astounding capability of nature to regenerate the necessities for the living organisms to space hardware is the task at hand for the MELiSSA scientists and engineers. In order to mimic an isolated ecosystem in space a multidisciplinary approach is inevitable. The MELiSSA community is comprised of 14 industrial and academic partners from all over Europe and Canada. The necessary fundamental and applied research is carried out by specialists from all thinkable fields in a collaborative effort. While microbiologists and chemists unravel the mechanisms of the involved microorganisms, mathematicians finding a way to model the concept, engineers of all domains build the hardware and integrate it in a closed loop. MELiSSA involves scientists from all ages and professions: flight tests aboard the ISS are carried out by astronauts to validate the MELiSSA loop in space. At the numerous universities partnered up with MELiSSA, the project generates vast research opportunities for undergraduate and graduate students. For secondary education MELiSSA is an opportunity to demonstrate the functioning of earth’s ecosystem while coupling it with the fascination of space. In addition high schoolers from all over Europe can help to generate data for MELiSSA, be it in science projects or in an effort like the MELiSSA education experiment carried out in May 2015 with over 1000 schools all over Europe.

European Space Agency 2015

MPP compartment IVb inside: A view of the "Greenhouse" used to cultivate higher plants for food and oxygen production.

Even though MELiSSA is intended for future space missions, its research contributes to terrestrial applications. Its novel technologies in the field of circular economy add to our quality of life today. To ensure food and water quality are challenges to be overcome in coming decades, where MELiSSA generates possible answers to. The MELiSSA loop strives to enable sustainable high density urban living and the possible development of formerly uninhabitable areas.

Richard Stoner’s AgriHouse, Inc. Aeroponics Food Growth System

Richard Stoner, AgriHouse, Inc., Berthoud, Colorado

Richard Stoner’s AgriHouse Inc. Aeroponic Growing systems

Richard Stoner, AgriHouse, Inc., Berthoud, Colorado

AgriHouse’s Aeroponic Root example with mist droplets on roots

Richard Stoner, AgriHouse, Inc., Berthoud, Colorado

AgriHouse’s Leaf Sensor Technology

The Aeroponic Food systems that have been developed in the past few years were done in conjunction with NASA. AgriHouse's Richard Stoner has pioneered this technology. The aeroponics systems have been tested on the International Space Station as a possible method of growing planets in space and during space exploration and future colonization. The system uses a concept of soil-less food growth by spraying the plant root systems with a nutrient based water with a "mist". The water droplets provide both water and nutrients in the water, a delivery means to the plants through this innovative delivery system. The plants can be grown in artificial and natural daylight. The latest ideas for the NZ4 Global Alliance applications have considered growing plants 24/7/365 with the use of both daylight and LED, "red shifted" lights to maximize growth. The water nutrient solution also uses a product called "BEYOND" which was developed with both NASA and AgriHouse to reduce plant diseases and increase growth by approximately 30%. At AgriHouse we look forward to acting as a information support system to help K-12 schools teach students about these innovative plant growth systems; thereby creating student enthusiasm for food growth systems of the future.

Dr. Addison Lawrence / truShrimp™ Vertical Aquaculture - Shrimp Growth System

Dr. A. Lawrence; truShrimp™Systems, Ralco, Marshall, Minnesota

Dr. A. Lawrence’s Vertical Shrimp Growing Production

Dr. A. Lawrence; truShrimp™Systems, Ralco, Marshall, Minnesota

Dr. A. Lawrence’s shrimp in the “runway”

Research for the development of the stack raceway system for the production of shrimp was initiated in 2001 and resulted in the issuance of US Patent Number 8,336,498. The stacked raceway system produces 500,000 to 1,500,000 lbs of shrimp per acre footprint of water per year depending upon a final harvest size of 10 to 30 gms per shrimp. Though the technology for producing the shrimp in the stacked raceway system is commercial this technology today is equivalent to that of chicken technology 25 to 35 years. The technology for producing shrimp in the stacked raceway system is being continuously improved. Obtained information is indicated that within ten years the technology for producing shrimp in the stack raceway system will make shrimp as cheap as chicken. Thus the farming of shrimp has the potential of increasing the world’s supply of high quality animal protein to meet the increasing demand due to the world’s human population doubling in the next 30 to 40 years. We look forward to working with K-12 schools to help students learn more about using vertical food production techniques for both earth bound systems and the potential to use these systems hopefully for space exploration and colonization on other planets. We look forward to K-12 school programs to produce the next generation of aquaculturists to manage the closed loop, sustainable and environmentally friendly food systems. The stacked raceway system patented technology was licensed to Ralco Nutrition, Inc. for commercialization.

Tamra Fakhoorian / GreenSun Products, LLC Duckweed Information:

Lemnaceae, Photo taken in Galicia, Spain; Source: Wikipedia 2015

An example of Duckweed

GreenSun Products, LLC specializes in duckweed production and applications. Founder, Tamra Fakhoorian became interested in duckweed while helping develop the algae for biofuel industry in the late 2000’s. Her company, GreenSun specializes in stand-alone, closed loop, and integrated duckweed production systems, as well as harvesting and solar drying systems. GreenSun Products, LLC includes product lines for both pet food and human nutrition. Duckweed’s high quality protein outcompetes soy production ten to one for the same space footprint. Duckweed can filter water sources such as those found in an NZ4 Global Alliance scenario with sustainable efficiency. Biomass can be used for bioenergy or animal feed. Closed systems can be used to produce biomass, fresh water, and oxygen from carbon dioxide, sun, and waste nutrients. GreenSun currently has projects developing in the US, Philippines, Mexico, and Australia.

In addition to Tamra’s expertise in both algal and duckweed production, in 2012,she co-founded and serves as Director for the International Lemna Association (ILA)- the first trade association in the world dedicated to commercial production of duckweed for feed, food, fuel, and fresh water. The ILA consists primarily of researchers and duckweed startups. Tamra also serves on the International Steering Committee for Duckweed Research and Applications where she helps produce the ISCDRA Journal- duckweed news and research.

Return to Teaching Tools for K-12; Aquaponics, Aeroponics, and Closed Loop Food Systems

This article originally appeared in the issue of .