Greenheck Announces Redesign for Energy Core Ventilator Line

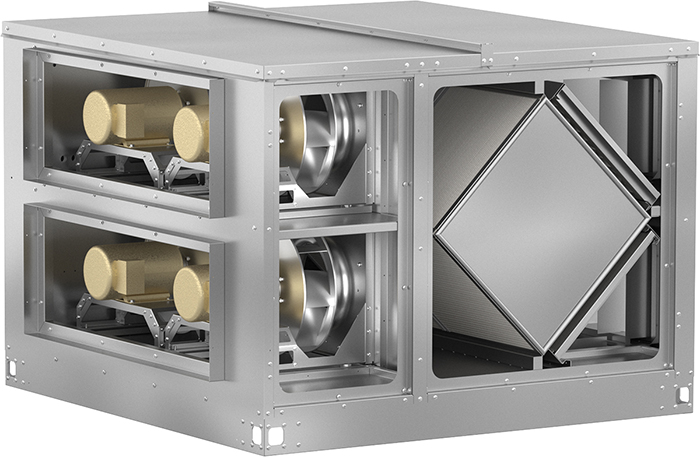

Air movement, control and conditioning solutions company Greenheck announced this week that it has redesigned its Energy Core Ventilator (ECV) line. According to a news release, the upgrade is meant to ensure the best possible unit performance within the smallest available footprint for space-sensitive installations either indoors or outdoors.

The press release states that the new ECV units feature direct drive plenum fans with variable frequency drives (VFDs). The new fans replace the more standard forward-curved fans to reduce motor horsepower requirements and the associated electrical wire and circuit breaker sizes. The VFD facilitates balancing during start-up, and the removal of belts simplifies maintenance procedures. It also features reduce sound power levels as backed by radiated sound data tested in accordance with AMCA 320-07.

Photo courtesy of Greenheck

The ECV line has an airflow capacity of up to 5,000 cfm and comes with an AHRI Certified fiber membrane core or washable polymer core. Other model ECV features include double-wall construction with optional lift-off or hinged access for flexibility during new or retrofit installations. The standalone microprocessor controls allow for the management of downstream electric heaters and heating or cooling coils. Other options include frost, fan speed and economizer controls.

The energy core ventilators were designed for environments like schools, residence halls, hospitals, nursing homes and offices, according to the news release.

About the Author

Matt Jones is senior editor of Spaces4Learning. He can be reached at [email protected].