Facilities (Learning Spaces)

High School Qualifies for Energy Rebates

PHOTO COURTESY OF SYDNEY HIGH SCHOOL

Today’s school facility managers and administrators have more on their plates than ever before. Tighter budgets, rising energy costs and taxpayer scrutiny for every dime spent all while trying to provide a high achieving education for students. Sidney High School is a comprehensive; college-prep oriented public high school in southwest Ohio, with about 1,000 students. The school faced many of these issues and made the decision to upgrade their energy stealing refrigeration equipment with advanced walk-in refrigeration technology.

Educational facilities in the U.S. and Canada spend about $16 billion on energy each year. Schools spend more on energy than any other expense except personnel. However, energy is one of the few expenses a school can reduce without sacrificing educational quality.

DataTrends, energy use intensity (EUI) ranges from less than 50 to more than 500 kBtu/per square foot across all schools, with those at the 95th percentile using four times the energy of those at the 5th percentile. The distribution has a negative slant, which means the most energy efficiency properties are further away from the median than the most efficient.

School properties may use more or less energy for many reasons, including variable equipment efficiency and energy management practices, as well as variations in climate and property activities.

Measuring energy is the first step

Electricity can be charged based on two measures: demand and consumption. The consumption part of the bill is based on the amount of electricity in kWh that the school building consumes each month. The demand part is the peak demand in kilowatts occurring within the month. Demand charges can vary widely, and the challenge is to reduce them whenever possible.

Sidney High School depends on a third-party refrigeration group to recommend energy-saving service practices and new refrigeration technologies. We, (Eck Refrigeration), approached the high school with a plan to compare their current refrigeration equipment to newer technology in a real-world field test location.

We’ve worked with Sidney High School for more than 30 years and were aware of the cafeteria’s refrigeration abilities and limitations. And we knew that a condenser upgrade would provide them with better efficiency.

The existing condensing unit was 15-years-old and part of the original equipment installed with the freezer. The freezer itself is a 20-foot by 20-foot walk-in style unit that is in constant use. The freezer runs all-year-round to hold foods from not only the high school, but also other schools in the system during the summer months. Although the existing condenser unit for the freezer was still operational, it used more energy and required more maintenance than in the past. The new product was energy efficient and would result in savings for the school versus the older unit. In addition, the upgrade could qualify for a utility rebate.

More, better for less. By replacing a 15-year-old, original equipment condenser for the high school’s large walk-in refrigeration unit, the school saved 36 percent on energy and qualified for a $966.51 rebate from their local utility company. By replacing older units with energy-efficient systems, schools benefit by saving energy costs, and often receive the additional benefit of less noise in sensitive areas. One other consideration is that newer technology sometimes includes built-in diagnostics, etc., so refrigeration technicians can get information quickly and accurately when troubleshooting problems, avoiding unnecessary service calls, and protecting the systems from premature failure.

The local utility, Dayton Power & Light (DP&L), was also interested in learning about the potential energy savings from this technology. They brought in Go Sustainable Energy to conduct pre-installation and post-installation metering of the Copeland refrigeration-condensing unit manufactured by Emerson. Metering equipment was installed to measure power, current and walkin freezer air temperature.

Saving energy and money

Field tests were conducted in a back-to-back test of the existing equipment and the energy saving solution. The location was instrumented with data acquisition systems that recorded temperatures and power consumption. The old condensing unit was run for over a month before being replaced with the new unit. The performance of the two units was compared during periods of similar weather and usage. The energy efficiency of the entire system was improved beyond initial expectations. The updated unit accounted for approximately 36 percent energy savings when compared to the old unit. Baseline peak demand was 5,270 W and the energy consumption 30,797 kWh per year. Based on post-installation logged data, estimated new peak demand is 4,551 W and the energy consumption is 19,614 kWh per year. This corresponds to a peak demand reduction of 719 W and an annual energy savings of 11,182 kWh per year. This project qualified for a $966.51 rebate.

Stretched facility budgets make low- or no-cost energy expenditure reductions especially important. School administrators can achieve energy savings of up to 25 percent through behavioral and operational changes. Easy changes include turning off lights and setting thermostats to 68 degrees for heating and 78 degrees for cooling.

Energy efficient products provide schools with the benefit of saved energy costs, and less noise in sensitive areas. The new condensing unit is mounted on the roof of the school and has a smaller footprint than the existing unit. It also came equipped with a rain cover so installation was much easier. Newer products also offer the additional benefit of less service calls in the long run.

Conclusion

The updated refrigeration unit accounted for approximately 36 percent energy savings when compared to traditional or standard condensing units. Unlike older models, built-in diagnostics provides refrigeration technicians information to quickly and accurately troubleshoot any issues, avoid unnecessary service calls, and protect the system from premature failure. This project qualified for a $967.00 custom utility rebate to offset total installation costs, significantly improving projected return on investment for subsequent equipment upgrades.

What characteristics affect energy use in schools?

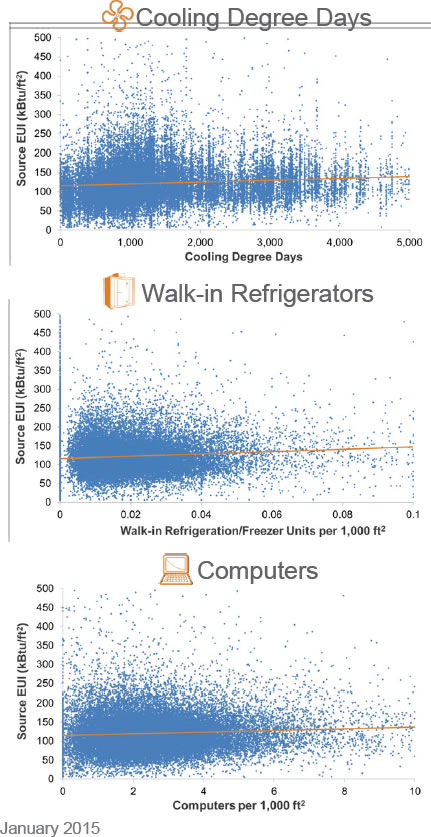

Typical activity and climate are often correlated with energy consumption. For example, schools that experience more cooling degree days (CDD), have more walk-in refrigerators (a measure of cafeteria activity), or more computers per square foot use more energy, on average. The orange trend lines in the graphs below show the impact of each characteristic on energy use. The steeper the line, the bigger the impact. While these trends hold true on average, the blue dots demonstrate that for any given value of CDD, walk-in refrigerators, and computers, a broad range in energy use is observed. Similar trends can be seen for other indicators of property activity. For example, energy use is higher for high schools than elementary schools.

This article originally appeared in the June 2017 issue of School Planning & Management.